Dairymaster has taken the manufacture and design of rotary milking to a new level, announcing the launch of their DM3X+ Rotary Milking Parlour which has been developed primarily to suit the performance needs of the very large commercial dairies.

These customers monitor parlour performance with standard industrial metrics such as throughput and uptime, and they seek to minimise both scheduled and unscheduled downtime. Dairymaster believe this product will strengthen their offering especially in export markets.

Dairy farming continues to grow outside of Europe, with typical farms milking thousands of cows three or even four times per day, all year round. Herd size for these farms is often determined by the number of cows that can be milked in an 8-hour shift. Milking parlour performance is everything to these commercial dairies with the parlour typically milking in excess of 21 hours per day, with the aim of milking one cow approximately every 6 seconds.

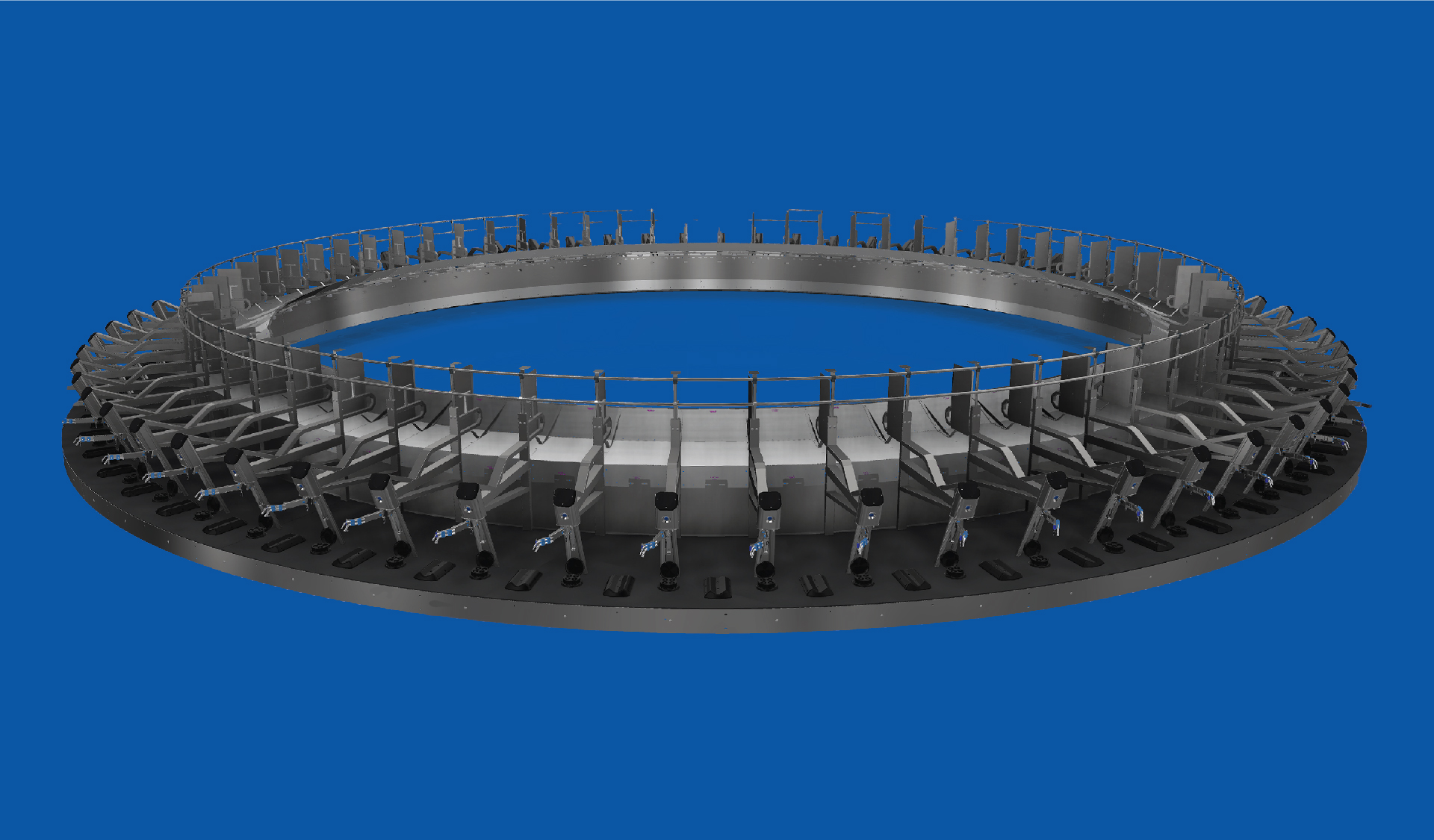

The DM3X+ is specially developed to meet the specific needs of these types of farms, and includes advances for equipment reliability, speed of operation and cow flow. The bail divider on the DM3X+ follows minimalistic design principles to expose only the essential functions at the point of operation.

The bail incorporates SmartSwitch technology, allowing the operator to quickly select the action they need. SmartSwitch is a traffic light like system whereby colour indicate various commands, for example, green for milking, blue for washing, red for stop etc.

The system is designed for speed of maintenance and has redundancy built into all major components to ensure continuous milking. The continuous milk flow ensures that cows are constantly milked, maximizing milking throughput and speed of milking meaning service can be done efficiently in between milkings.

Dairymaster’s experience worldwide allowed them to redesign the platform to promote cow comfort so that the cows can load and unload quickly and stress free. The rotary deck is built to withstand the increased workload by incorporating extra redundancy in the drive systems and the patented Rotaglide track technology.

Some of the technology will be applicable to owner-operator dairy farms, and they will look to incorporate the suitable aspects into the existing rotary parlour designs where appropriate.